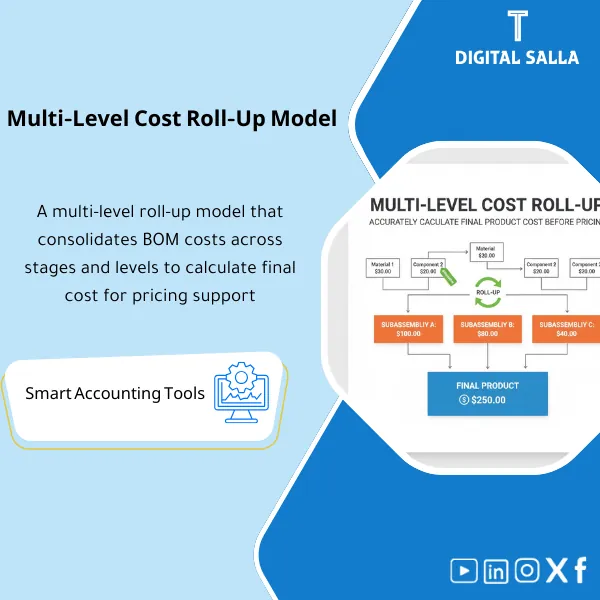

Multi-level BOM Cost Roll-up – Excel Template

84.84 $

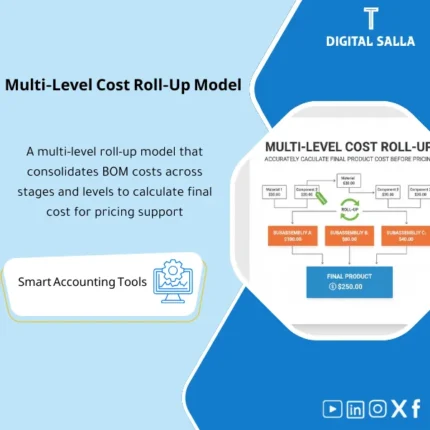

Multi-Level BOM Cost Roll-Up: Aggregates component and subassembly costs across BOM levels to estimate finished product cost pre-production. Delivers cost roll-ups and alternative cost scenarios to support standard cost updates and pricing reviews.

Multi-level BOM Cost Roll-up Template

A practical template (Excel/Costing Pack) for calculating Final Product Cost through Multi-level BOM Cost Roll-up (FG → Subassemblies → Components) with support for versions and effective dates, updating component costs, and performing BOM Change Impact Analysis on unit cost and margin.

Value Proposition: Instead of relying on “estimated costs” or manual collection of components, this template performs an automatic Roll-up of costs at each level of the BOM until reaching the final product cost, with clear breakdown: Materials + Conversion/Operating + Overhead (optional) + Scrap/Yield (optional).

In 20 seconds: What will you get?

- Multi-level Cost Roll-up: Calculate FG cost across all levels of the BOM (including Subassemblies).

- Subassembly Costing: Automatically calculate the cost of each subassembly from its components.

- Version & Effective Date: Compare BOM costs by version/effective date (Current vs New).

- Change Impact: Report on “what impact does changing quantity/component/alternative” have on unit cost.

- Component Cost Updates: A central page for updating material/component costs (Purchase/Standard/Last).

- Cost Breakdown: Breakdown of costs by (Level / Component Type / Make vs Buy).

- Controls: Identify components with no cost, BOM loops (Circular), duplicates, and mismatched units of measure.

- Scenario Analysis: Scenarios for “new supplier price” or “material alternative” or “increasing Scrap%.”

- Dashboard: Top products by cost/change in cost/most impactful components.

- Export-ready: Cost summary per unit suitable for pricing/standard cost/update in ERP.

Delivery associated with the button: BOM Master + Cost Table + Roll-up + Change Impact + Dashboard + Controls.

Suitable for

- Factories with multiple manufacturing levels: (FG → Subassembly → Parts).

- Pricing/Product Teams: Want to accurately calculate unit cost before pricing or before bids.

- Engineering/Industrialization: Assessing the impact of BOM changes (ECO) on cost.

- Finance/Costing: Updating Standard Cost and comparing “old vs new” costs.

Not Suitable for

- If there is no approved BOM or quantities/units are not consistently defined.

- If you need complete engineering management (PLM) with workflow approvals — this is outside the scope of the Excel template.

- If the BOM is too complex with thousands of items and requires database processing — you can start with the template and then convert it to a larger tool.

Without the template / With the template

| Item | Without the template | With the template |

|---|---|---|

| FG Cost Calculation | Manual/Approximate/Unverified collection | Automatic Roll-up across all levels of the BOM |

| Subassembly Cost | Unclear/Calculated once and forgotten | Automatically calculated and updated with any change in components |

| BOM Changes (ECO) | “We only know the impact after a while” | Change Impact shows the cost delta immediately |

| Data Quality Control | Incorrect costs due to missing Costs or duplicates | Error/Warning list (Missing Cost / Circular BOM) |

Before Use: 5 Symptoms That You Need Multi-level Cost Roll-up

- Material prices change frequently, but the final product cost is not updated systematically.

- Multiple Subassemblies exist, and no one knows the cost of each subassembly “today.”

- Every change in the BOM leads to lengthy discussions: “Is the cost increase 3% or 12%?”

- Difficulty in identifying “the most impactful component” on product cost (Cost Driver) for alternative/negotiation decisions.

- Pricing new products without a clear defensible Cost Breakdown in front of management or audit.

What Does the Multi-level BOM Cost Roll-up Template Cover?

It covers the journey “from raw BOM table to precise unit cost” through:

BOM Data Cleaning → Component Cost Identification → Multi-level Roll-up →

Change Impact Analysis → Outputs ready for pricing/Standard Cost.

Key Definitions (Simply)

- Single-level BOM: Components at a single level for a product.

- Multi-level BOM: Components + subassemblies that also contain BOMs.

- Roll-up: Summing component costs across levels to reach the final product cost.

- Where-used: Where this component is used within products/assemblies.

- Effectivity: Date/period of validity of the BOM version (before/after engineering change).

Implementation Method (6 Steps)

Step 1: Prepare BOM Data

- Unified table structure: Parent | Component | Qty per | UOM | Scrap% (optional) | Version | Effective From/To.

- Determine if the Component is “Purchased” or “Manufactured/Subassembly.”

Step 2: Enter Component Cost Table

- Cost Table for components: Material Cost | Last Purchase | Standard | Currency | Vendor (optional).

- You can add Landed Cost/Packaging/Other Add-ons if needed.

Step 3: Calculate Subassembly Costs

- The cost of each Subassembly is calculated from its components (even if Subassemblies are within Subassemblies).

- Display the level (Level) for easier review.

Step 4: Roll-up for FG Cost

- FG Cost = Sum (Qty × Cost) for each component after calculating the cost of subassemblies.

- Optional: Apply Scrap/Yield to consumption quantity or waste cost.

Step 5: Analyze Change Impact

- Compare BOM Version A vs Version B or Baseline vs Scenario.

- Show “Top 10 Components driving delta” to identify the cause of increase/decrease.

Step 6: Output Results for Use

- Unit Cost + Cost Breakdown for use in pricing or updating Standard Cost in ERP.

- Review report: Missing Costs / Circular BOM / UOM Issues before finalizing results.

Product Components (Clear Inventory)

-

BOM Master (Multi-level BOM Structure)

- Fields: Parent | Component | Qty per | UOM | Level (calculated/optional) | Version | Effective Dates | Make/Buy.

- Purpose: Source of truth for product structure and its branches.

-

Item/Component Cost Table (Component Costs)

- Fields: Item | Cost Type | Standard/Last/Avg | Currency | Updated Date | Notes.

- Purpose: Quick update of material costs linked to the Roll-up.

-

Subassembly Cost Sheet (Subassembly Costs)

- Outputs: Cost of each Subassembly + Breakdown of its components + Depth level.

- Benefit: Knowing “block costs” within the product instead of just seeing FG.

-

Roll-up Engine (Cost Roll-up Engine)

- Outputs: Total FG Cost | Unit Cost | Cost Breakdown by Level/Type.

- Options: Scrap/Yield | Additional Add-ons | Conversion/OH (optional).

-

Change Impact Analyzer (BOM Change Impact Analysis)

- Outputs: Delta Cost vs Baseline + List of top impactful components.

- Cases: Material alternative, quantity change, component deletion/addition, subassembly change.

-

Where-used Report (Where the component is used)

- Outputs: List of products/assemblies that will be affected if the cost of this component changes.

- Benefit: Support negotiation with suppliers and manage risks of price increases.

-

Data Quality Controls (Data Quality Controls)

- Checks: Missing Cost | Circular BOM | Duplicate Lines | UOM mismatch | Negative Qty.

- Benefit: Prevent approval of incorrect costs due to uncontrolled BOM data.

-

Dashboard (Dashboard)

- KPIs: Highest FG Cost | Highest Cost Delta | Most Impactful Component | Cost distribution by BOM levels.

Suggested Tabs within the Delivery File

- BOM | Costs | Roll-up | Subassemblies | Change Impact | Where-used | Controls | Dashboard.

After Implementation (Only Two Points)

- Result for Product/Engineering: You will immediately know the impact of any change in the BOM or material alternatives on unit cost, before approving the change.

- Result for Finance/Pricing: You will have a reviewable Unit Cost and Cost Breakdown, making it easier to update Standard Cost and explain any changes in margins.

FAQ — Questions Before Purchase

Does the template support multiple BOM versions and effective dates?

Yes. You can enter Version and Effective From/To and then compare costs “before/after” (Baseline vs New).

How does the template handle Subassemblies?

If the component is “Manufactured/Subassembly” and has a BOM, the template will calculate its cost from its components and then roll it up to the higher level automatically.

Does it support Scrap/Yield?

Yes (optional). You can enter Scrap% or Yield Factor to adjust consumption/cost and show the impact of waste on Unit Cost.

Can OH or Conversion cost be included?

Yes as an option: either add a fixed Conversion Cost for each Subassembly/FG, or add OH as a value/percentage within the assemblies according to your policy.

(If you need advanced OH based on hours/work centers, it is best to link it with Routing/Work Centers or Job Costing models).

How does the template ensure result accuracy?

Through the Controls tab that reveals: components with no cost, BOM loops, duplicates, UOM issues.

Before approving any Cost Roll-up, review the warning list and resolve them.

Can it be used for pricing (Cost-Plus)?

Yes. Because it provides a detailed Unit Cost, you can add a target margin (Markup) and analyze the impact of BOM changes on price/margin.

If your goal is to accurately calculate the final product cost through multi-level BOM + analyze the impact of BOM changes

Outputs: FG Unit Cost + Subassembly Costs + Change Impact + Where-used + Dashboard + Data Controls.

| المسمّى الوظيفي | |

|---|---|

| Duration | |

| المستوى | |

| التحديثات | |

| القطاع | |

| الصيغة |

Reviews

Clear filtersThere are no reviews yet.