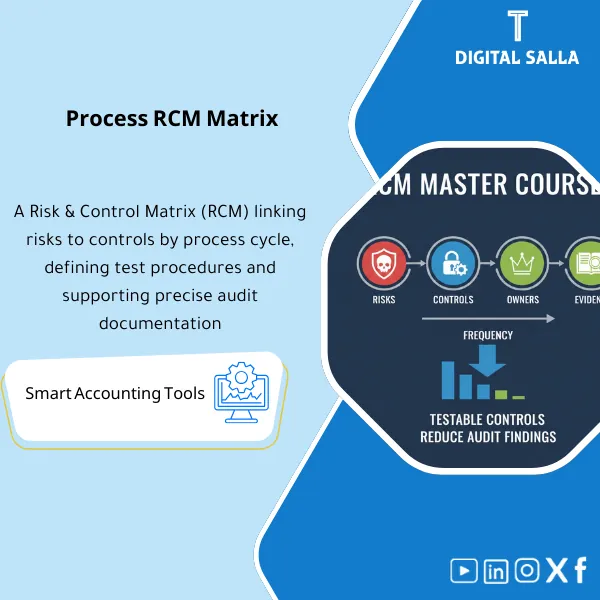

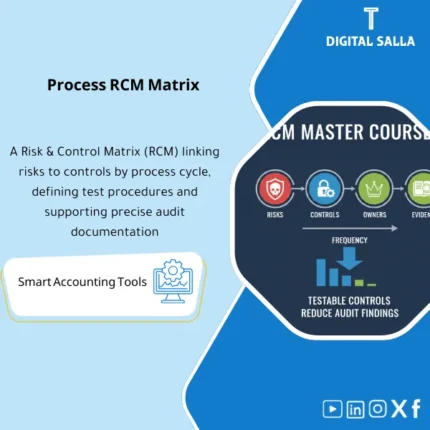

RCM – Risk & Control Matrix – Excel File

111.44 $

Risk & Controls Matrix (RCM): Covers key cycles (O2C/P2P/Inventory/Payroll/Treasury) including risks, controls, owners, evidence, and frequency. Delivers a testable RCM for internal audit planning and execution.

Risk and Control Matrix (RCM)

Risk & Control Matrix for Core Cycles + Key Controls + Control Testing Plan + Evidence Index + Deficiencies Log

Value Proposition: The RCM for core cycles connects “Risk” to “Control” and “Testing and Evidence”: Process → Risks → Controls (Design) → Test of Controls → Evidence → Deficiency & Remediation instead of unrelated control lists or undocumented tests.

In 20 Seconds: What Will You Get?

- RCM for Core Cycles: Common Risks + Corresponding Controls + Control Objectives (Prevent/Detect).

- Control Attributes: Control Frequency, Control Owner, System/Manual, Evidence Level.

- Key Controls Identification: Distinguishing critical controls relied upon for closing/reporting.

- Test of Controls Templates: Design/Operational Testing Approach + Sample Size + Testing Steps.

- Evidence Index: Where to find evidence for each control (Report name, screenshots, approvals, logs).

- Deficiency Log: Categorizing observations (Design/Operating) + Impact + Recommendation.

- Remediation Tracker: Remediation Plan + Responsible Party + Closure Date + Retesting.

CTA related to deliverables: Receive RCM + Test Plan + Logs to operate a reviewable and deliverable control program.

Suitable For

- Internal Audit to build RCM and control tests for core cycles.

- Financial Controller to document key controls that safeguard closing and report quality.

- External Audit Liaison to prepare the control evidence file and reduce document requests.

Not Suitable For

- Those seeking a “100% ready matrix” without alignment to the company’s system and authorizations (the RCM needs customization).

- Those without any control evidence (no reports/no workflow approvals) — you will need to build the evidence first.

Without RCM / With RCM (Quick Comparison)

| Item | Without RCM | With RCM |

|---|---|---|

| Linking Risks | Disparate tests that do not cover critical risks | Risk → Control → Test → Evidence in a single pathway |

| Testing Controls | Non-standardized steps | Standardized Templates (Design/Operating + sample) |

| Evidence | Late search for documents | Evidence index specifies the report/attachment for each control |

Before Use: 5 Symptoms Present in Controls

- Controls are “typically” present but undocumented with no owner or defined frequency.

- Risks in the purchasing/sales cycle recur (pricing/credits/data adjustments) without clear key controls.

- Control tests are conducted differently each time with no consistent methodology or sample size.

- Control evidence (reports/screenshots/approvals) is gathered only upon auditor request.

- Observations recur because there is no remediation tracker and retesting after closure.

RCM: Implementation Method (3 Steps Without Gaps)

Step 1: Identify Cycles and Risks

- Define the scope of cycles: Purchases/AP, Sales/AR, Inventory, Payroll.

- Identify critical risks for each cycle (Authorization, completeness, accuracy, cut-off, fraud).

- Determine where risks appear in the system/documents (workflow, approvals, access rights, reports).

Step 2: Document Controls and Their Attributes

- Record controls: Control description, type (Prevent/Detect), frequency, owner, manual/automated.

- Distinguish Key Controls and specify expected evidence (report/log/screenshot/signature).

- Prepare Evidence index with the location of evidence for each control.

Step 3: Testing Plan + Results + Remediation

- Build Test plan: Operational/Design testing approach + sample size + testing period.

- Document testing results and log any observations in the Deficiency log.

- Track closure through the Remediation tracker then retest and close the case.

Product Components (Clear Inventory)

-

RCM for Purchases/AP

- Practical Purpose: Risks (Vendor master, PO approvals, 3-way match, payment controls) + Controls + Evidence.

- When Used: Annually + Periodic Testing.

- Resulting Evidence: Completed matrix + key controls + evidence map.

-

RCM for Sales/AR

- Practical Purpose: Risks (pricing, credit, dispatch/invoicing cut-off, returns) + Controls + Evidence.

- When Used: Annually + Periodic Testing.

- Resulting Evidence: Matrix covering revenue, collections, and receivables.

-

RCM for Inventory

- Practical Purpose: Risks (receipts/issues, adjustments, counts, obsolescence) + Controls + Evidence.

- When Used: According to inventory cycle and reporting.

- Resulting Evidence: Inventory controls, reconciliations, movements, and adjustments.

-

RCM for Payroll

- Practical Purpose: Risks (master data changes, approvals, payroll run, bank file) + Controls + Evidence.

- When Used: Monthly for the payroll cycle + Periodic Testing.

- Resulting Evidence: Controls for data changes, payroll approvals, and payments.

-

Control Testing Templates

- Practical Purpose: Steps for operational/design testing + sample + result + attachments.

- When Used: When implementing the control testing program.

- Resulting Evidence: Standardized workpapers for testing results.

-

Evidence Index + Deficiency Log + Remediation Tracker

- Practical Purpose: Indexing evidence + managing observations, remediation, and retesting.

- When Used: Throughout the year during testing and follow-up.

- Resulting Evidence: Comprehensive file for governance and documentation.

CTA related to deliverables: RCM + Testing templates + Logs to operate a control program for core cycles.

What Should Be Included in the Deliverable?

- RCM sheets for each cycle (Purchases/Sales/Inventory/Payroll).

- Key controls list + attributes for each control (frequency/owner/evidence).

- Test plan + testing steps + sample size.

- Evidence index (report names/locations of screenshots/approvals).

- Deficiency log + impact assessment + recommendations.

- Remediation tracker + retesting + closure.

- Sign-off for the annual reference version (Version/Date).

After Implementation

- Operationally: Control tests become standardized and can be repeated over the years.

- Oversight: Each observation has an owner, a remediation plan, and retesting instead of repeating the same weakness.

FAQ

Is RCM suitable for SOX only?

No. It is applicable to any governance/internal audit framework. You can adapt the risk classification and testing level according to your requirements.

Can additional cycles (Treasury/FA/ITGC) be added?

Yes. The structure allows for adding other cycles following the same logic (Risk → Control → Test → Evidence).

Does it include Control Testing?

It includes templates, a testing plan, and documentation of results. Actual testing execution depends on your team and available data.

Does it work with any ERP?

Yes, as long as evidence (reports, logs, approvals) can be extracted to support the operation of controls.

Ready to document and test controls with the same approach?

| المسمّى الوظيفي | |

|---|---|

| Duration | |

| المستوى | |

| التحديثات | |

| القطاع | |

| الصيغة |

Reviews

Clear filtersThere are no reviews yet.